Houston’s Top Mold Design Providers

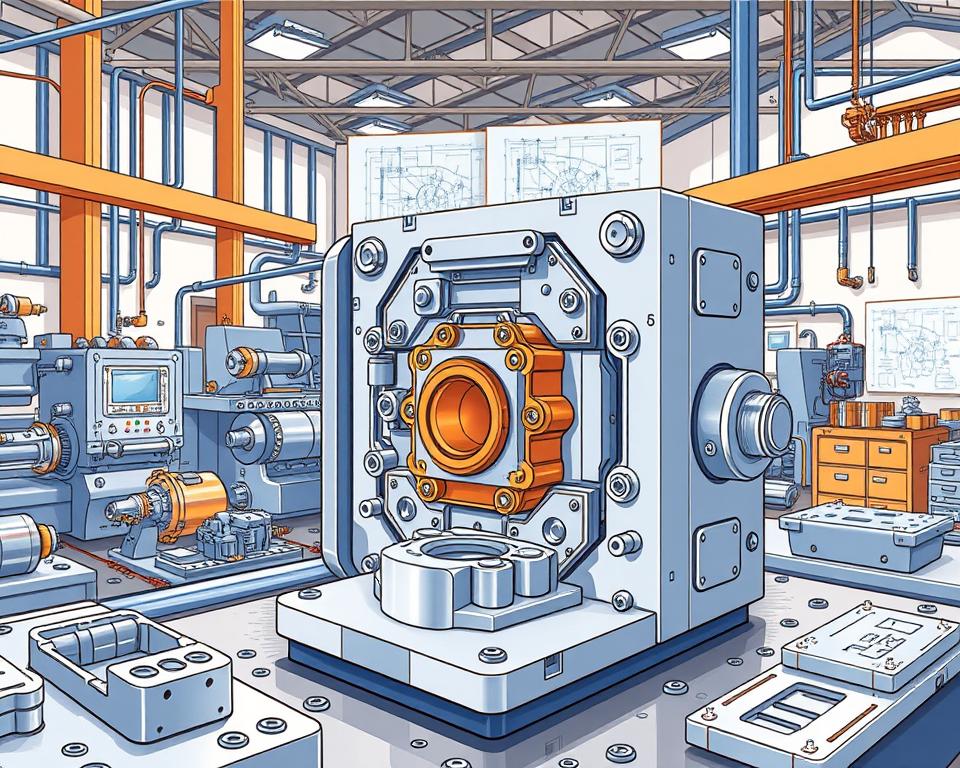

By 2025, the global injection molded plastics market will reach $440 billion. This growth underlines the importance of professional mold design services. They deliver bespoke, top-tier mold designs across multiple sectors. In Houston, Lowrance Machine is a leading mold design company. They offer innovative solutions for automotive, aerospace, and consumer products.

With CAD and 3D-printing at its core, Lowrance Machine. Their specialists deliver efficient, highly precise mold production. Their seasoned experience and engineering prowess make them a dependable collaborator. Discover how their injection molds Houston offerings improve project outcomes and satisfy current market needs.

Why Mold Design Services Matter

Mold design services are vital in the manufacturing world, affecting product quality and operational efficiency. The role of mold design is immense; it shapes the performance and longevity of products. Companies that invest in expert mold design can cut production costs and improve quality standards.

Seasoned professionals at Lowrance Machine illustrate the benefits of expertise. They engage closely with clients to develop tailored designs. By employing cutting-edge methods like 3D modeling and CAD, they help businesses create molds that adhere to high standards.

Selecting expert mold design partners enhances product output and propels company performance. Effective mold design leads to efficient manufacturing, giving companies a competitive edge in the market.

Houston Mold Design: Service Categories

Lowrance Machine offers a wide range of mold design Houston services, tailored to meet specific industry needs. Understanding each mold service type guides firms to the perfect choice for their tasks. Key categories include:

- Custom Design Solutions: Custom mold design solutions that cater to unique specifications and requirements.

- Test Mold Creation: Prototype mold development for pre-production testing.

- Injection Mold Fabrication: Precision-engineered injection molds built to last.

- 3D Modeling: 3D-model-driven design for superior precision.

- Mold Repair & Upkeep: Preventive and corrective mold maintenance to prolong tool life.

All offerings focus on efficient production, improved product standards, and cost savings. Knowing the service spectrum lets companies tailor mold design to their operational objectives.

Benefits of Choosing Professional Mold Design Experts

Partnering with seasoned mold designers yields multiple manufacturing benefits. Gain improved accuracy, robustness, and throughput. Tailored molds ensure top-notch quality and repeatable outcomes.

Veteran designers inject invaluable process optimizations. Their knowledge ensures designs meet industry standards and unique specifications. Working together drives creative solutions and lengthens product durability.

Saving on production is a major advantage. Modern techniques curb scrap and shorten lead times. This results in substantial savings, boosting a manufacturing operation’s financial health. Fast-turnaround designs accelerate product launches.

To conclude, expert mold designers are indispensable for production firms. They aim to optimize production capabilities and enhance product offerings.

Cutting-Edge Mold Design Methods

The field of mold design has seen a major leap forward thanks to technological advancements. Pioneering these advances, Lowrance Machine adopts the latest techniques. Such breakthroughs accelerate production and raise standards. Modern engineering tools expedite custom mold fabrication and lower overheads.

Additive manufacturing shines by producing fast prototypes and intricate shapes. It cuts scrap dramatically versus conventional tooling. Virtual simulation tools let engineers validate and optimize molds digitally for better accuracy and speed.

In Houston, mold design experts are embracing these modern strategies. Organizations sharpen their standing by utilizing digital modeling and state-of-the-art fabrication. They facilitate flexible, rapid-response mold development to satisfy diverse applications.

| Technique | Description | Benefits |

|---|---|---|

| 3D Printing | Harnesses 3D-printer tech for swift mold fabrication. | Reduces lead time and material waste. |

| Simulation Software | Visualizes mold design through computer models. | Enhances accuracy and optimizes performance. |

| Digital Design Tools | Leverages CAD for detailed mold engineering. | Supports bespoke specifications and rapid revisions. |

In Closing

Mold design services are critical for businesses aiming at efficient manufacturing and high-quality production in Houston. Professional mold design services offer expertise to tackle mold development challenges. They customize approaches to align with specific business goals.

Renowned for precision and teamwork, Lowrance Machine leads the mold design field. Bespoke molds and innovative methods from professionals maintain market leadership. Working with mold design experts improves product quality and streamlines operations.

Investing in professional mold design in Houston focuses on quality and efficiency. Businesses can meet customer expectations effectively and gain a significant competitive advantage. Leveraging professional mold design is crucial for success in a crowded industry.